Cockle Cylinder

Price 95000 INR/ Pair

Cockle Cylinder Specification

- Product Type

- Cockle Cylinder

- General Use

- Grain cleaning and cockle separation

- Capacity

- 50-100 kg/h Kg

- Weight (kg)

- 200 kg Tonne

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Voltage

- 220V Statampere (sA)

- Dimension (L*W*H)

- 2000x800x1200 mm Meter (m)

- Raw Material

- Rice

- Feature

- Compact Structure, High Efficiency, Lower Energy Consumption

- Color

- White

- Warranty

- 1 Year

Cockle Cylinder Trade Information

- Minimum Order Quantity

- 1 , , Pair

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 , , Pair Per Day

- Delivery Time

- 7 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Cockle Cylinder

Specification

|

Capacity |

0 - 4,10 - 19,5 - 9 |

|

Use |

Commercial |

|

Design |

Standard |

|

Noise |

No |

|

Multigrain |

Yes |

|

After Sales Service |

Yes |

|

Certifications |

ISO9001-2008 |

|

Warranty |

12 months |

|

Condition |

New |

|

Operation Mode |

Automatic |

|

Power Rating |

1-5 HP |

|

Capacity ( ton per day) |

10 to 19,5 to 9 |

|

Installation Services Required |

Yes |

|

Capacity (Ton/Day) |

0 to 5,5 to 10 |

|

Usage/Application |

Grading |

|

Features |

Rotary |

A cyclone cylinder, also known as a cyclone dust collector or cyclone separator, is a device used to separate particles from the air or gas stream using centrifugal force. Here's a detailed overview

Working Principle

The cyclone cylinder works by creating a spinning motion in the air or gas stream, which forces particles towards the walls of the cylinder.

The particles are then collected in a hopper or bin, while the clean air exits through the outlet.

Key Features

-High EfficiencyCyclone cylinders can achieve high collection efficiencies, often above 90%, for particles larger than 5-10 microns.

Simple DesignWith few moving parts, cyclone cylinders are relatively simple to operate and maintain.

Cost-EffectiveCompared to other dust collection systems, cyclone cylinders are often more cost-effective and energy-efficient.

Applications

Industrial Settings Cyclone cylinders are commonly used in various industries, such as woodworking, metalworking, pharmaceuticals, and food processing.

Air Pollution Control They are also used in air pollution control systems to remove particulate matter and other pollutants from gas streams.

Benefits

Improved Air QualityCyclone cylinders help maintain a cleaner and healthier work environment by removing airborne particles.

Reduced Downtim By minimizing dust buildup and preventing equipment damage, cyclone cylinders can help reduce downtime and increase productivity.

ComplianceThey can help industries meet regulatory requirements and standards for air quality and emissions

We are manufacturing, exporting and supplying best quality Cockle Cylinders in Hapur, Uttar Pradesh, India. Applied in flour mills, rice grading plant, barley plant, corn plant and other cereal mills and plants. It is ideal for cleaning and grading of diverse grains. Moreover, it can be availed from us at reasonable costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller Flour Mill Plant Category

Impact Detacher

Price 90000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

General Use : Grinding

Automatic : Yes

Computerized : No

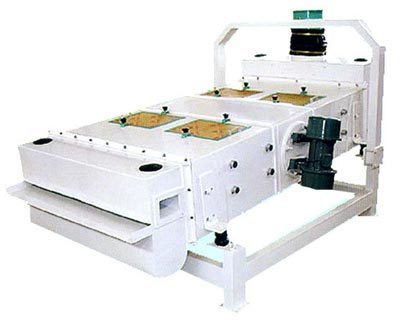

Plansifter Machine

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

General Use : Flour Sieving

Automatic : Yes

Computerized : No

Vibro Separator

Price 165000 INR / Set

Minimum Order Quantity : 1 Set

Material : Galvanized Steel

General Use : Grain Cleaning

Automatic : Yes

Computerized : No

Bran Finisher

Price 125000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Galvanized Steel

General Use : Flour Sieving

Automatic : Yes

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free